Nanotech Energy Inc. has unveiled Nanotech EMI Armour Paint & Sheets, graphene powered coatings and films for electromagnetic interference (EMI) and radio frequency interference (RFI) shielding, as well as heat management. The EMI Shielding line currently contains six products – all of which are highly conductive and provide excellent external EMI/RFI protection while also preventing internal EMI/RFI leaks. The products can be sprayed, brushed, rolled or dip-coated onto various surfaces, such as glass, plastic and metal. Graphene antennas are printed on paper to enable customers to pay their bill by tapping their smartphone on the receipt. The company has also announced that in the first quarter of 2021, mass production willl start on non-flammable, efficient and fast-charging lithium-ion 18650 Batteries. These cell-type batteries are used in devices including, but not limited to, laptop computers, cordless power tools, safer electric vehicles, telecommunications, aerospace and military applications. The Company has begun taking pre-orders.

Xiaomi has launched a crowdfunding campaign for its new graphene-based smart heating mattress. The graphene layer in the mattress is used to generate heat, and according to the company the graphene enables uniform heating without the overheating or overcooling problems that are inherent in traditional heating mattress.

Edmonton International Airport (YEG) will host a trial for a new graphene-based COVID-19 testing technology that can produce results in seconds. The trials will be executed in partnership with GLC Medical, a subsidiary of Graphene Leaders Canada (GLC). The test is conducted with a handheld unit that takes a saliva sample from a person and is expected to tell if someone has COVID-19 in under one minute, compared to other tests with longer laboratory-based waiting periods for results. This test promises many advantages, from its ease of use to the elimination of the nasal swab to direct virus detection.

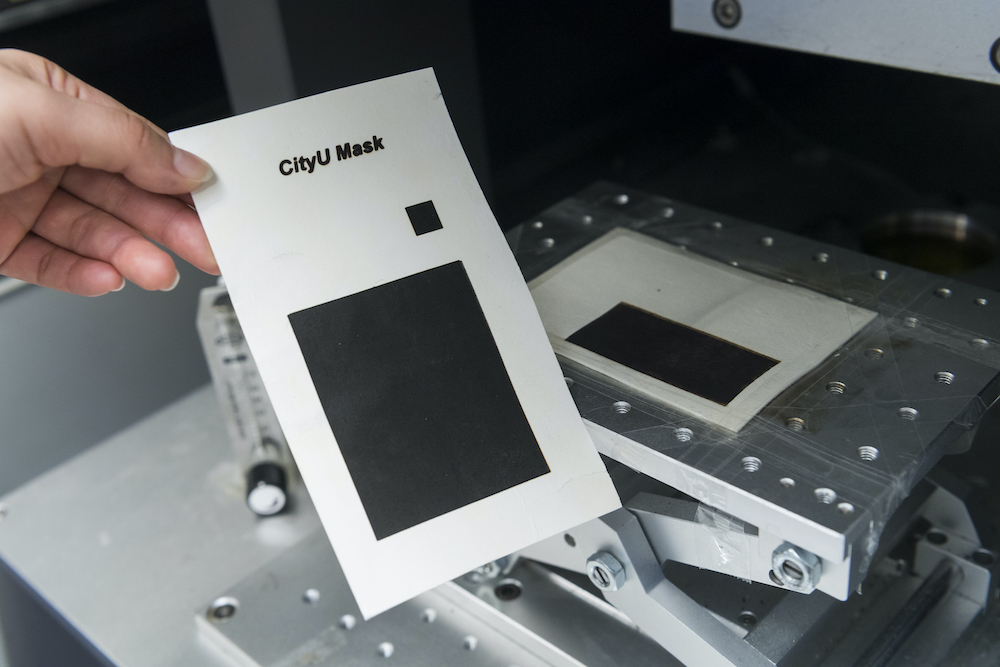

Researchers from City University of Hong Kong (CityU) has developed graphene masks with a reported anti-bacterial efficiency of 80%, which can be enhanced to almost 100% with exposure to sunlight for around 10 minutes. Initial tests also showed very promising results in the deactivation of two species of coronaviruses. The graphene masks are reportedly easily produced at a low cost, and can help to resolve the problems of sourcing raw materials and disposing of non-biodegradable masks. The research team tested their laser-induced graphene with E. coli, and it achieved high anti-bacterial efficiency of about 82%.

Applied Graphene Materials PLC has launched a new graphene-enhanced car polishing product in partnership with Infinity Wax, a specialist car care distributor. The spray, QDX Graphene Detailing Spray, is designed to enhance the shine of a vehicle and make it much easier to wipe any dirt away.

MITO Material Solutions has developed a proprietary graphene-functionalization technique that produces unique strength-enhancing additives for a wide variety of polymers and composites. The additives significantly improve mechanical properties (including tensile strength, flexural modulus and others) of the plastics and composites, allowing manufacturers to replace metals in a range of applications requiring high strength and light weight. In late August, MITO announced $1 million in seed funding, led by two Chicago-based firms, Dipalo Ventures and Clean Energy Trust. The company is also supported by a Small Business Innovation Research (SBIR) grant from the National Science Foundation.

NanoXplore Inc. has announced completion of the commissioning of its state-of-the-art 4,000 metric tons/year commercial graphene capacity facility in Montreal, Province of Quebec. NanoXplore’s new graphene facility is a fully automated production plant that enables a connected, flexible and continuous manufacturing system. Production automation ensures the highest level of product quality, from receipt of raw materials, to final packaging of NanoXplore’s GrapheneBlackTM powders.

ZEN Graphene Solutions has developed a novel graphene-based virucidal ink with 99% effectiveness against COVID-19. ZEN’s Virucidal ink is 99% effective a minimum of 35 days after application to N95 mask material.ZEN is now developing plans to expedite commercialization of this product, pending regulatory approval, and has filed a provisional patent for this graphene-based virucidal product. The company has received results from the latest round of testing of its proprietary, virucidal graphene-based ink formulation at Western University’s ImPaKT facility Biosafety Level 3 laboratory.

Two graphene-based ink samples at different concentrations were applied to N95 mask filtration media and then exposed to the SARS-CoV-2 virus that causes COVID-19 and tested for antiviral properties in accordance with ISO 18184:2019.

SpaceBlue has invented and developed a graphene-enhanced recycled rubber floor mat to address the global problem of waste tyre, currently being burned or going to landfill. The company is a Manchester-based start-up (started with the support of the Graphene Engineering Innovation Centre at the University of Manchester) that came up with a novel solution to address the waste tyre issue by developing a graphene-enhanced recycled rubber product-the SpaceMat.

SpaceMat is a flooring product that uses graphene to improve dramatically the performance of recycled tire rubber compared to previous efforts. It’s estimated that 1.5 billion waste tires are generated globally every year and most end up in landfill or being burned. Numerous attempts have been made to produce high-quality recycled rubber from tires, but the shedding of microparticles from resultant products has raised concerns over environmental health.

Chinese EV maker Guangzhou Automobile New Energy (GAC) has developed a graphene-enhanced battery for EVs which will be available for mass production at the end of this year. The company has recently set up a unit that specializes in graphene and has begun research and development of fast-charging technology for electric vehicles. GAC demonstrated a super-fast charging battery at its annual tech day in July. Test data showed that it could be charged up to 80% within eight minutes. The battery’s corresponding cores, modules and battery pack samples have since passed preliminary function and performance tests.

Nano Graphene Inc., has developed an antimicrobial product to protect glass surfaces in public and private places from dangerous microorganisms. The company has developed a new graphene-improved ceramic-based coating with a built-in antimicrobial additive for protection of various types of glass for up to 2 years. The superhydrophobic coating constantly guards surfaces, which is particularly important in-between the regular cleaning cycles. Produced jointly with a global aerospace specialty coating maker, the antimicrobial product is user-friendly and easy to apply. Once applied, it dries within 20 minutes, and is invisible to the human eye.

The coating is applied on glass doors, storefronts, and plexiglass protective shields at banks, shops, and offices, as well as in taxicabs and mass transit.

Skeleton Technologies has partnered with the Karlsruhe Institute of Technology, one of the largest research and educational institutions in Germany, to complete the development of the SuperBattery, a groundbreaking graphene battery with a 15-second charging time. This extra fast charging time coupled with charging cycles counted in hundreds of thousands make the SuperBattery a perfect solution for the three main issues affecting electric vehicles: slow charging times, battery degradation, and range anxiety. The key differentiator for the SuperBattery is Skeleton’s patented Curved Graphene carbon material, enabling the high power and long lifetime of ultracapacitors to be applied in a graphene battery. Ultracapacitors are increasingly emerging as the ideal complementary technology to lithium-ion batteries, as also shown by Tesla’s acquisition of ultracapacitor manufacturer Maxwell Technologies in the hopes of improving batteries used in Tesla’s electric vehicles.

Archer Materials has developed a new set of graphene materials that could be applied for enhanced biosensing and to aid in the development of biocompatible inks in water-based solvents. “There is no doubt that diseases have a devastating effect on economies and there is value in advancing disease diagnosis using simpler, more accurate biosensors,” Archer CEO Dr Mohammad Choucair said. “However, there are only a limited number of materials that can perform [biosensing], and they require innovative development.”

“We have rapidly advanced from raw material feedstock to prototypes of a portable battery-powered sensing device that can incorporate biological material,” Choucair said. “This early stage work has the potential to allow much simpler and more effective sensing where early diagnosis of life-threatening diseases can lead to much improved outcomes.”